Product Information

Guardian Shield™ Panels Provide a Lifetime of Savings

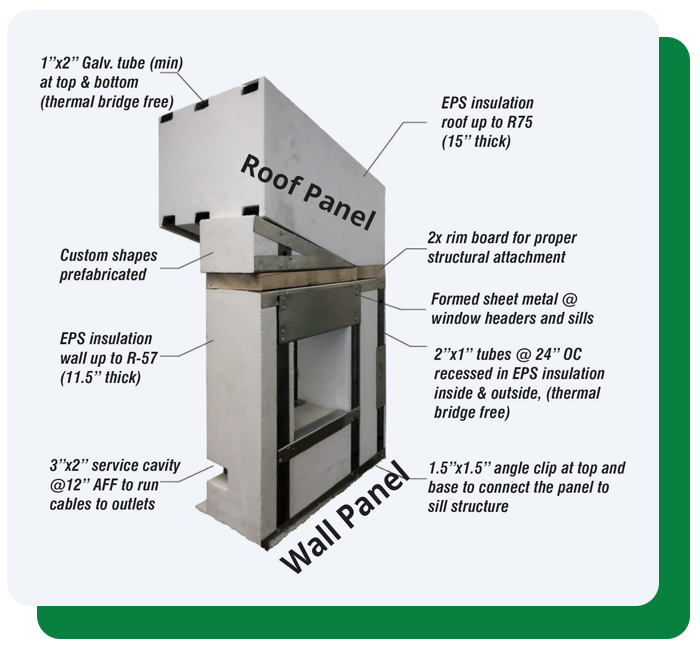

Guardian Shield Panels are a high-performance engineered thermal envelope panel system that utilizes cold formed steel as the structural members which are embedded in energy efficient Expanded Polystyrene (EPS).

Construction Benefits for Builders:

Construction Benefits for Builders:

- Track Record – over 40 years of performance in the most challenging environments.

- Sustainable - Components made from 100% recyclable material.

- Efficient Construction – Reduction of the rough construction of the exterior envelope by over 50%. There is no need for an insulation contractor and mechanicals are easily installed.

- All-in One System – The panels are engineered and supplied per the construction plans – rough openings for windows & doors. Panels come with all necessary components for installation including interior wall attachments.

- Panels can be utilized for Basements, Walls, and Roofs – Total Exterior envelope.

- No Waste – Components are designed to be used in total, with no waste or need for a dumpster.

- Light Weight - Panels can be placed by hand or a Lull or Gradall.

- No Special Equipment Required – Can be installed by rough carpentry or light gauge steel crew.

- Parallel Path - Panels can be manufactured while foundation is completed and shipped to site when ready.

- Reduced HVAC Equipment Sizing and Cost – HVAC system design will be more efficient, less costly, quicker installation, integrated hot water system and smaller footprint.

- Easily Field Modifiable – Panels can be modified in the field if needed.

- ROI – The customer/owner/operator’s energy efficiency is a value add and can command a premium price.

- Cost Savings – With all the realized savings, product quality, time value of money and the savings due to the quick assembly translates to the bottom line - making SHIELD™ a cost-effective solution.

- Flexible Design Capabilities - From single family homes to multifamily, commercial to industrial, hospitality to hospital; we provide the building envelope to your exact design.

- Environmental Tax Rebates – Panels are Passive House Institute United States (PHIUS), Leadership in Energy and Environmental Design (LEED) and Net Zero capable designs.

Lifetime of Benefits for Owners & Occupants:

- Sustainable – No degradation of EPS insulative qualities and long-life components.

- Healthy – Panels are inert and have no off-gassing, while the system provides high air quality (low air infiltration).

- Extreme Insulative Qualities – provide R-Values of up to R-75.

- Energy-Efficient - Reduce heating and cooling costs by 75 to 85% over conventional construction methods.

- Load-Bearing – Engineered-stamped to ensure true structural integrity.

- Durability and Longevity - By reducing thermal stress and moisture infiltration, a well-designed thermal envelope can extend the lifespan of building materials and structural components, reducing maintenance costs over time.

- Reduces Deforestation – Saves 20 mature Douglas Fir trees for every 1,000 square feet of stick construction.

- Resilience to Extreme Weather - A robust thermal envelope provides protection against extreme weather conditions, such as heatwaves, cold snaps, heavy rain, and windstorms, enhancing building resilience & occupant safety.

- Moisture Resistant – Panels are moisture and mold resistant- panels don’t decay, expand or warp.

- Sound/Noise reduction – Additional characteristic of the panels is the inherent sound reduction from the EPS.

- Environmental Impact – Homeowner is contributing to the conservation of energy resources, while reducing their overall environmental footprint.

Lasting Cost Savings

Shield™ Panels provide a lifetime of savings for the building owner.

- Energy-efficient Shield™ buildings use less energy, thus reduced utility costs (Up to 40% of a home's heat loss is due to air leakage)

- HVAC equipment is designed to operate more efficiently

- Superior building envelope with high thermal resistance and minimal air infiltration

- Heavy-duty components provide building durability from environmental elements

Shield™ Panels cost savings “Optimize your gains and losses" based on climate.

How Shield™ Panels Work

Shield™ Panels achieve structural integrity with an “I” beam effect by using galvanized steel studs as the flanges of the “I” beam and a rigid plastic foam core of expanded polystyrene (EPS) as the web of the “I” beam.

The key to its structural performance is that the galvanized steel studs are inserted flush with the EPS core on both sides and fastened with industrial grade metal fasteners. This design prevents exterior and interior finishing materials from buckling. The rigid 1-pound per square foot EPS core serves as both the insulated component and web of the “I” beam panel. The thicker the SHIELD™ Panel, the more load they are able to carry and the greater the R-Value.

Shield™ Panels SPS (Structural Panel System):

SHIELD™ Panels are a unique building product because they combine superior structural support and insulation in one panel, but without the weight and difficult maneuverability of typical SIPs. However, SHIELD™ Panels, like SIPs, are available in various thicknesses and sizes, up to 12’ x 40’.

How Shield™ Panels Are Similar to Stick & SIPs Construction:

Switching from stick-built to a SHIELD™ Panel is a very easy process that requires few changes. Many standard tools are still used when building with SHIELD™ Panels. But unlike the power lifting equipment required for SIPs panels, which can weigh up to 800 pounds, SHIELD™ Panels can be lifted by as little as one or two installers. Also, SHIELD™ Panels are extremely friendly to field modifications if required. To aid in learning the process of installing SHIELD™ Panels, Guardian Structural Technology offers on-site installation training or recommends experienced installation teams.

How Shield™ Panels Surpass SIPs and ICF Construction:

SHIELD™ Panels evolved from stick-built and SIPs construction, which use dimensional lumber for corner connections and plates. Compared with stick framing, SIPs and ICFs, constructing with SHIELD™ Panels eliminates steps, lightens material handling and time is saved.

How They Have Consistent Quality:

The galvanized steel studs and EPS foam core are rigidly fastened together in the factory with high-grade industrial screw under strict quality control standards. Fabrication of SHIELD™ Panels buildings includes precision cutting and shaping of each panel to match specification and exact shop drawings.

Shield™ Panels Galvanized Steel Stud Framing:

There are many reasons why steel framing has come to the forefront as one of the best and most feasible alternative building materials for residential and commercial construction. Steel is a superior construction material with many benefits.

More Product Information:

Guardian Panels Differentiation sheet 3-part Specification Technical Product SpecificationsShield™ Panels Building System and the Environment

It is important to keep in mind that all insulation and building materials have an environmental footprint. In fact, most modern buildings and insulation materials are quite carbon-intensive to produce. Cement, for example, produces huge amounts of CO2 in production, as do insulating materials like rockwool and fiberglass. However, Expanded Polystyrene (EPS) insulation is 98% AIR and can return up to 200 times the amount of energy required to produce it and reduce emissions by up to 100 times the volume produced during the manufacturing process. EPS is non-toxic and totally inert. It contains no Chlorofluorocarbons (CFCs) or Hydrofluorocarbons (HCFCs), and never has at any time during its life cycle. It is also totally absent of any nutritional value, so no fungi, mold, or micro-organisms can grow within EPS. Structures built with SHIELD Panels experience very low air infiltration creating controlled interior environments with high fresh filtered air supplies for the occupants.

Read More >

Cold Formed Steel (CFS) meets the highest sustainability requirements set in all major green building standards and rating programs, including Passive House Institute United States (PHIUS), Leadership in Energy and Environmental Design (LEED) and National Green Building Standard (ICC-700) for residential buildings. CFS framing has infinite recyclability. Every year, more than 65 million tons of steel are recycled, according to the American Iron and Steel Institute. CFS framing contains a minimum of 25 percent recycled steel and is continually and completely recyclable. Using recycled steel takes the pressure off renewable resources: if built with wood, a 2000-square-foot home would require about 40 to 50 trees. With steel, only the equivalent of about six recycled automobiles is needed for the same size home.

SHIELD™ PANELS being made of Expanded Polystyrene and Cold Formed Steel are much lighter than alternative building techniques, thereby saving significant transportation emissions. The Expanded Polystyrene and Cold Formed Steel that Guardian Structural Technologies uses in the SHIELD™ Panels building system contains recycled content EPS and CFS. All the scrap of EPS and CFS from our manufacturing is completely recycled. The Guardian Structural Technologies SHIELD™ Panels building system virtually eliminates job site waist.

Guardian Structural Technologies is committed to helping owners meet their high-performance building needs with a structural envelope system that provides superior technical, environmental, and financial benefits for the life of the building. SHIELD™ Panels building system delivers not only short-term construction cost savings, but long-term environmental and financial benefits as well.

Passive Housing

Passive building consists of design principles used to attain a measurable level of energy efficiency within a specific quantifiable comfort level in any type of building. We are the first, and currently the only, panel system in the US that is certified by the Passive Housing Institute US (PHIUS).

The 5 Passive Housing Scientific Principles:

- Employs continuous insulation throughout its entire envelope without and thermal bridging.

- The building envelope is extremely airtight, preventing infiltration of outside air and loss of conditioned air.

- Employs high performance windows and doors- solar gain is managed to exploit the sun's energy for heating purposes in the heating season & to minimize overheating during the cooling season.

- Uses some form of balanced heat - and moisture-recovery ventilation.

- Uses a minimal space conditioning season.

Source: phius.org

To view the full PHIUS certificate for the SHIELD™ Panels system by Guardian Structural Technologies, click here or on the certificate image below.

Comparison of Shield™ Panels Versus Other Wall Constructions

Versus Traditional Stick Construction

- Stick construction is labor intensive

- Framers required for stick construction can be difficult to retain (shortage of available skilled framers)

- Air sealing of stick construction is labor intensive and expensive

- Wood is susceptible to rot and pest infestation

- Stick construction requires separate contractor to install insulation

- Thermal bridging through wood studs and plates – results in very low thermal efficiency (R-Values)

- Stick building presents design limitations

- SHIELD™ Panels are quick to install and require less skilled labor

- R-Values of SHIELD™ Panels are substantially higher

- Labor costs to install SHIELD™ Panels are less

- Time to erect building using SHIELD™ Panels is substantially less than time required to construct stick frame

Versus Masonry Construction

- Material costs of masonry are extremely high

- Masonry walls have no R-Value and require substantial additional materials to insulate

- Installation of masonry requires highly skilled laborers who are expensive to employ and difficult to locate

- Masonry difficult to insulate – expensive and labor intensive

- SHIELD™ Panels can easily accommodate masonry veneer for stone or brick exterior look

- Masonry retains moisture and dampness, requiring ventilation

- Masonry building presents design limitations

- SHIELD™ Panels are quick to install and require less skilled labor

- R-Values of SHIELD™ Panels are substantially higher

- Total material costs (including required insulation) of SHIELD™ Panels is substantially less expensive

- Labor costs to install SHIELD™ Panels are a small fraction of the most of installing masonry

- Time to erect building using SHIELD™ Panels is substantially less than time required to construct with masonry

Versus Steel Framing

- Substantial thermal bridging issues with steel framing

- Steel framing construction is labor intensive

- Framers required for steel framing construction can be difficult to retain (shortage of available skilled framers)

- Air sealing of steel frame construction is labor intensive and expensive

- Steel framing construction requires substantial cross bracing

- Steel framing construction requires separate contractor to install insulation

- SHIELD™ Panels are quick to install and require less skilled labor

- R-Values of SHIELD™ Panels are substantially higher

- Material costs of steel framing construction are comparable with SHIELD™ Panels

- Labor costs to install SHIELD™ Panels are less

Versus SIPS Construction

- Structural strength of SIPS construction relies on the adhesive used to attach sheathing to EPS – as the adhesive or sheathing deteriorate over time the structural strength of the building diminishes

- SIPS panels present design limitation as they can only be used for buildings of limited height

- Sheathing of SIPS panels susceptible to rot and pest infestation

- SIPS panels require specialized installation knowledge and skills

- R-Values of SHIELD™ Panels and SIPS panels are very close

- Material costs of SIPS panels are comparable to SHIELD™ panels

- Limitations on thickness of SIPS panels limit potential R-Values

Versus Insulated Concrete Forms (ICFS)

- Material costs of ICFs are very high

- Installation of ICF walls requires use of costly concrete pumps and complicated bracing

- Installation of ICFs is extremely labor intensive

- Time required to install ICFs is very lengthy

- ICFs require specialized installation knowledge and skills

- No roofing applications because of use of concrete in the interior space